Accessories

Anchor & Mooring

Blocks Allen

Blocks Wichard

Fasteners

Furlers

Hull & Deck Hardware

Maintenance

Rigging Hardware

Rudder & Tiller

Safety & Webbing

Spar & Sail Hardware

Storage & Protection

Tapes

Tools & Machinery

Tracks & Travellers

Forsheda Mooring Compensator

Mooring compensator.

Forsheda are easy to fit requiring no extra fittings. Made of ECO EPDM rubber and recycled black carbon, this mooring compensator diminishes the strain of wind, waves and wake. Keeps lines from snapping and prevents cleats from pulling out. It is impervious to the elements, strong sunlight, salt water and obstinate moorings. No squeaking, no wear, no tear!

| Part | Description | Rope Ø mm | RRP Inc VAT |

Unit | |

|---|---|---|---|---|---|

| FS-450082 | Forsheda Size 1 | 10 - 12 | £27.91 | EACH | |

| FS-450092 | Forsheda Size 2 | 14 - 16 | £39.01 | EACH | |

| FS-450102 | Forsheda Size 3 | 18 - 20 | £62.89 | EACH | |

| FS-450112 | Forsheda Size 4 | 22 - 24 | £112.66 | EACH |

Eco-Friendly mooring compensators

Powerful forces come into play when wind starts to blow. It is not only the wind that gives rise to disastrous stresses and strains. The swells resulting from passing boats, high and low tides are all factors that can cause a lot of trouble. The mooring compensators diminishes the strain of wind, waves and wake. Keeps lines from snapping and prevents cleats from pulling out.

The mooring compensators that you have trusted for years has now transformed to eco-friendly ones after a long development phase. The new generation of mooring compensators are made up of 100% ECO EPDM rubber and recycled black carbon, with a composed total of more than 60% green material.

With vigorous testing, our R&D department has ensured that the green mooring compensators would perform as good as the original material that our customers rely on, if not better!

The extensive testing period gives us the confidence that the original Forsheda mooring compensators are now even better with green materials and we are proud to supply you with this new generation of eco-friendly mooring compensators instead.

Choose Green! Protect your boat with the eco-friendly mooring compensators.

Made of ECO EPDM rubber and recycled black carbon, this mooring compensator diminishes the strain of wind, waves and wake. Keeps lines from snapping and prevents cleats from pulling out. It is impervious to the elements, strong sunlight, salt water and obstinate moorings. No squeaking, no wear, no tear!

Locking the line

Our mooring compensators are equipped with locking elements at both ends that are vulcanized into the compensator. This system locks the line securely without the need of any extra fittings.

Easy to fit

Thread the mooring line through the holes for an easy and secure fitting and all is ready!

Four sizes

Simply choose the size according to our guide, fit the rope around the mooring compensator in a three-stranded fashion and you are good to go!

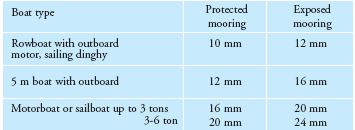

In choosing the proper line thickness, the following examples may serve as a guide (Recommendations of Swedish boat insurance companies).

First determine what line thickness you need on the basis of the size of the boat and situation of the moorage. For secure mooring, we recommend a three-stranded line of synthetic material.

In choosing the proper line thickness, the following examples may serve as a guide.

First determine what line thickness you need on the basis of the size of the boat and situation of the moorage. For secure mooring, we recommend a three-stranded line of synthetic material.

The extension of the compensator can be varied by changing the number of times the line is wound around it. The more turns, the further the compensator can extend. You can set the extension you want. In narrow mooring places, e.g. between Y booms, one or two turns is usually right. In exposed moorings, the line should be winded three times. Consider going up one size in mooring line diameter and compensator.

The table gives the maximum movement in mm for different numbers of turns and the force which a straightened compensator takes up with three time winding. More than three turns greatly shortens the life of the compensator due to large compensating movements.

contact us

Proboat Ltd

Burnham Business Park,

Burnham - on - Crouch,

Essex,

CM0 8TE, UK

Phone - +44 (0)1621-785455

E mail - info@proboat.co.uk

Burnham Business Park,

Burnham - on - Crouch,

Essex,

CM0 8TE, UK

Phone - +44 (0)1621-785455

E mail - info@proboat.co.uk

info

Terms and conditions

Privacy Policy

Downloads

Stockists

Products

Trade account

Copyright © 2018 Proboat Ltd.

All rights reserved.

Privacy Policy

Downloads

Stockists

Products

Trade account

Copyright © 2018 Proboat Ltd.

All rights reserved.

disclaimer

Although great care is taken to ensure the

information in this website is accurate, all information is given for

guidance only and is not contractual.

We reserve the right to alter specifications without notice. The purchaser is responsible for choosing the correct product for it's particular application.

All goods are supplied according to our conditions of sale.

We reserve the right to alter specifications without notice. The purchaser is responsible for choosing the correct product for it's particular application.

All goods are supplied according to our conditions of sale.